SearchUser loginOffice of CitizenRest in Peace,

Who's new

|

Firestone Tire Wilderness AT 235 75R 15 bead cord failureSubmitted by Jeff Buster on Sat, 12/03/2011 - 11:50.

It turns out that this tire was included in the Firestone Tire safety recall implemented in 2001 - however, the tire failed because of a different manufacturing defect than the steel belt separation defects cited in the recall. The tires in the recall failed - according to what I have read including a technical report titled Firestone Tire Failure Analysis by Dr. Sanjay Govindjee - due to a separation of rubber between the steel tread belts.

You can read the statement about Firestone tire failures made by Joan Claybrook On Firestone Tire Defect and Ford Explorer Rollovers to the United States Senate Committee on Commerce, Science and Transportation on September 12, 2000.

Read the National Highway Traffic Safety Administration's Firestone Tire Recall statements here.

The tire imaged above is one of the same batch of defective tires - but the failure mode is not in the tread area but in the exterior tire cord at the bead. In an effort to examine why the tire bead failed a razor knife was used to cut into the rubber at the right hand side of the image (see top image) . In the razor cut the cord fibers can be seen in the upper and lower faces of the cut. The fiber location in the rubber rises to the surface of the rubber on the hand side of the image -while the fibers are buried about 3/32" of an inch in the rubber on the right hand side.

Looking further to the left along the cracked rubber in the image the failed cord fibers have left residual thread sized grooves/corrugations in the surface of the rubber on both sides of the crack.

It is clear that the failure mode for this tire was chaffing of the cord fibers by the steel wheel rim because the cord fibers were in direct contact with the steel rim because there was no rubber cover between the rim and the fiber.

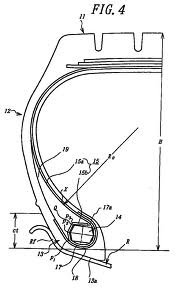

The following image from data.epo.org is a diagram of a typical tire bead with cord wrapped around the bead.

You can find many more images of tire bead/cord here on Google Images.

The Wilderness AT tire has an agressive tread and in this case was being used on the rear axel as a winter snow tire on a Chevy 1500 van. The driver of the van - very fortunately - heard a squeaking noise form the rear of the vehicle at very slow speed - and assumed it was a brake which was squeaking. The operator asked another person to drive the vehicle slowly so that the operator could walk alongside the vehicle and listen to determine which rear wheel made the noise.

Once it was determined which wheel made the once per revolution squeak, the vehicle as jacked up and the wheel removed in order to inspect the brake drum.

Only when the wheel was off the vehicle so the inside of the wheel was visible did the operator notice that the bead on about one third of the steel rim was lifting outwardly away from the rim leaving a 1/8th inch to 1/4" inch gap.

The tire was inflated to 35 lbs and other than the gap between the bead and the steel rim nothing looked wrong with the tire.

The operator put on the vehicle spare and this tire stayed on the rim outside until a few days ago when I helped dismount the tire.

Only when the tire was dismounted from the steel rim was the cracked rubber visible. Note: the rust stain on the tire is a product of the squeaking tire polishing the steel rim which then rusted orange in the rain after the tire was removed from the vehicle.

The tire was manufactured in the tenth week of 1998 at with VNHL factory code - see image below for DOT manufacturing information

The image below demonstrates the extent of the bead cord failure on the whitewall side of the tire. None of the cracks were visible while the tire was on the steel rim - because the rim extends to the raised ridge on the tire - see rust stain which extends to the raised rubber ridge.

Read at Public Citizen about how corporations value us - Ford and Firestone valued us?

( categories: )

|

Recent comments

Popular contentToday's:All time:Last viewed:

|